Inductive Proximity Sensors

Carlo Gavazzi is a market leader in inductive proximity sensor technology with one of the broadest range of products in the industry. With over 40 years of experience, Carlo Gavazzi knows what it takes to manufacture sensors that are designed to withstand the rigours of your toughest applications. With local sales and support centers located in 22 countries and independent distribution in over 100 countries, Carlo Gavazzi product and technical support is available around the world.

What is an Inductive Sensor?

Inductive proximity sensors detect metallic objects (both ferrous and non-ferrous metals.) There are three primary parts to an inductive sensor: inductive coil with oscillator, evaluation circuit, and output circuit. When an oscillating signal is applied to the coil, a magnetic field is created. The presence of metal disrupts the magnetic field and is detected by the evaluation circuit, which energizes an output signal. Inductive sensing technology allows targets to be detected without contact while ignoring most environmental influences such as reflected light, dirt, debris, and oil.

The target material is important to identify since most metals are compounds and not pure. Technical data and specifications for inductive sensors are based on ferrous steel. If the target material is stainless steel, aluminum, brass, copper, etc., a reduction factor will need to be applied to the sensing range.

Sensing Range Derating Factor| Material | Derating Factor | Type of Material |

|---|---|---|

| Steel (Fe 360) | 1.0 | Ferrous |

| Chrome Nickel (CrNi) | 0.6 - 0.8 | Non-Ferrous |

| Brass (CuZn) | 0.35 - 0.5 | Non-Ferrous |

| Aluminum (Al) | 0.3 - 0.5 | Non-Ferrous |

| Copper (Cu) | 0.25 - 0.3 | Non-Ferrous |

The output of an inductive proximity sensor could be an NPN or PNP transisitor, SCR, relay or an IO-Link interface. IO-Link is a point to point communication protocol that allows for remote configuration and communication - allowing access to advanced diagnostic information. Typically, the sensor will connect to a multi-port IO-Link master which will allow a bus connection to your controller. In addition, we offer a hand-held configurator that allows the sensor to be configured as standard NPN or PNP output sensors and can be adapted to most applications. This is a powerful feature for distributor sales and customer maintenance.

How to Properly Select an Inductive Proximity Sensor

There are several factors to consider when selecting the best inductive proximity sensor for your application. These considerations can be broken down into five categories, which can be found on this TOP TIPS resource paper we did in conjunction with Machine Design and Electronic Design. View

Our Inductive Proximity Sensor Range

Applications for Inductive Proximity Sensors

Mobile Equipment utilize proximity sensors in order to monitor the position of lift arms, forks, compaction cylinders, truck beds, position of stability outriggers and to ensure that doors and gates are in position and locked.

Sensors used in these applications need to withstand mechanical shock and vibration, wide temperature ranges, transient over-voltages, high pressure washdowns, and interference from communication devices. CARLO GAVAZZI's ICS E1 Rated Sensors are designed to survive these conditions.

Food and beverage machinery requires sensors that can withstand moisture, cleaning agents, and extended temperatures. Our ICF Series of Sensors offers a full stainless steel housing with IP69K protection and ECOLAB® certification.

For machnery which features many types of sensors, IO-Link is built into our sensors and are a cost effective method of obtaining data from the various discrete and analogue signals. IO-Link Masters allow connection of sensors and provide a bus connection to read the data from your machine controller.

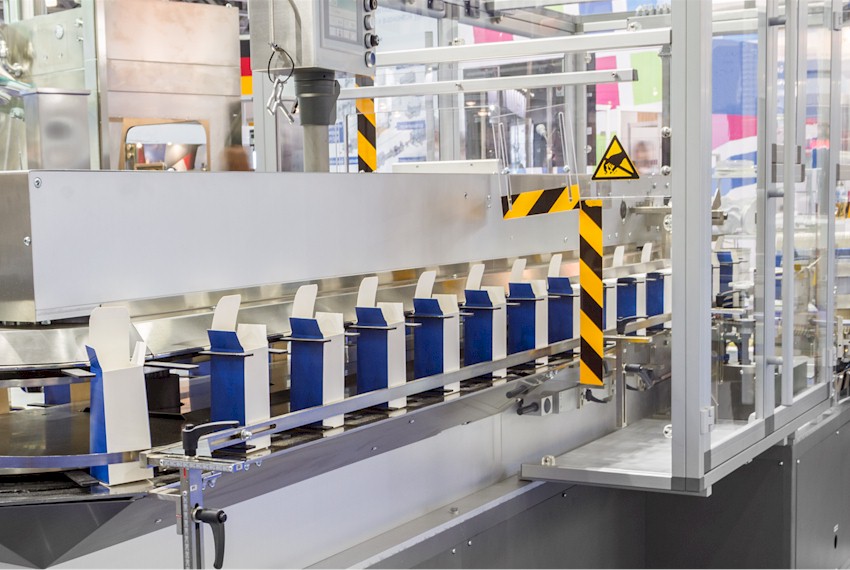

Inductive sensors are commonly used on pharmaceutical machinery for conveyor speed monitoring, monitoring if guards and guide ways are in place, and detection of metal caps on product containers.

Our sensors also feature IO-Link for ease of configuring, wiring and data access.

Inductive sensors are used extensively on packaging machinery. The sensors are used for monitoring of conveyor speed, gate monitoring and parts detection.

Our sensors include built-in IO-Link which allows the sensors to be monitored by your controller - with the data being used to predict problems in the applicaiton such as mis-aligned sensors.

Inductive sensors are used on long transport conveyors found in mining and other resource based industries. The sensors are used for monitoring of conveyor speed, gate monitoring and positioning.

Many of our sensors include built-in IO-Link which allows the sensors to be configured for RPM monitoring which can be tied to the sensor output - if a conveyor slows down, the sensor is able to detect this and provide an output.

Close

Close